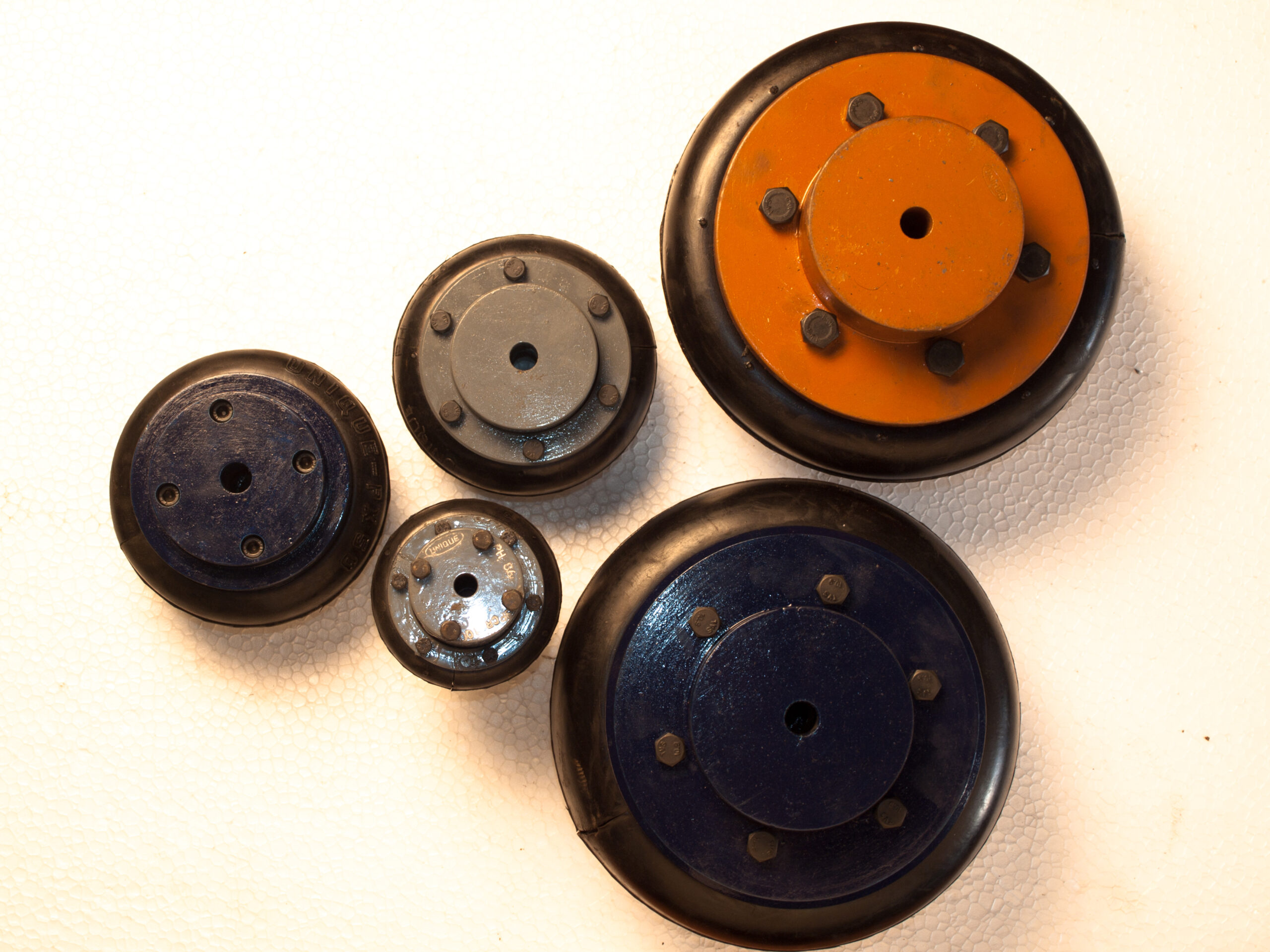

Shaft couplings are crucial in the realm of mechanical engineering and power transmission. These devices connect two shafts together at their ends to transmit power, accommodating misalignments and compensating for movement and vibration between connected shafts. In this blog post, we’ll explore the basics of shaft couplings, their functions, and their applications.

What Are Shaft Couplings?

At their core, shaft couplings serve as connectors that link two rotating shafts to ensure smooth and efficient power transmission. They play a critical role in various machinery and equipment, providing flexibility, protection, and alignment correction.

Key Functions of Shaft Couplings

- Power Transmission: Shaft couplings enable the transfer of rotational power from one shaft to another, ensuring machinery operates effectively.

- Misalignment Compensation: Couplings can accommodate different types of misalignments between connected shafts, such as angular, parallel, and axial misalignments.

- Vibration Damping: They help in absorbing and dampening vibrations, protecting equipment from undue stress and wear.

- Shock Absorption: By absorbing shocks during operations, couplings minimize the impact on connected components, enhancing the lifespan of machinery.

- Maintenance and Assembly: Couplings simplify the assembly and disassembly of machine parts, making maintenance tasks easier and more efficient.

Applications of Shaft Couplings

Shaft couplings find their use across various industries:

- Automotive Industry: Used in vehicle driveshafts, couplings ensure efficient power transmission from the engine to the wheels.

- Industrial Machinery: In machines like pumps, compressors, and conveyors, couplings facilitate smooth operation and alignment correction.

- Power Generation: Couplings in turbines and generators help in the transmission of mechanical power to electrical power.

- Marine Applications: Shaft couplings are vital in ship propulsion systems, connecting the engine to the propeller shaft.

Conclusion

Shaft couplings are indispensable components in mechanical power transmission systems, providing flexibility, protection, and efficient power transfer. Understanding their key functions and applications is crucial for engineers and technicians to design and maintain effective mechanical systems.